Time : March 15, 2024

Rolling of Austenitic Stainless Steel 302 and 304

Due to the contamination of the steel liquid by adding Ti to austenitic stainless steel, TiN and Ti (CN) inclusions are formed in the steel. The production of Ti containing austenitic stainless steel abroad is very small (only 0.5%), so 302 and 304 austenitic stainless steel without Ti has been widely used. 302 steel grade is equivalent to 1Cr18Ni9304 steel grade is equivalent to 0Cr18Ni9.

In a factory in the former Soviet Union, the heating time for 800kg of 1Cr18Ni9 and 1Cr18Ni9Ti steel ingots was 11.6min/cm, while in another factory, 400kg of steel ingots required 15.3min/cm. Cherianbinsky Steel Plant heated 1200kg of 1C18Ni9 and 1Cr18Ni9Ti steel ingots, with a furnace tail temperature below 800 ℃. Heating Z for a short time of 10 hours resulted in a high temperature of 1260 ℃, and the Z-short time for producing 4-5 steel ingots was controlled at 44-57 minutes.

Small steel ingots with a heating weight of 600-700kg and a large cross-sectional size of 270-305mm are heated in a continuous heating furnace in China. The same heating curve is applied, with a furnace tail temperature below 800 ℃, a high temperature of 1200-1240 ℃, and a short heating time of no less than 4.5-5.5h. The ingots should be kept at high temperatures for 30-50min. 0-2Cr18Ni9 steel ingots weighing 3000-3500kg are heated in a soaking furnace. The heating time for cold steel ingots is not less than 9.5 hours, and the high heating temperature for Z is 1280 ℃. The insulation time in the high temperature zone needs 3-4 hours; The total heating time of red steel ingots can be shortened to 8 hours, and the corresponding insulation time can be reduced to 1-1.5 hours.

Reheating the rolled steel billet in a walking beam continuous heating furnace can eliminate the surface temperature difference of the billet and improve the heating speed of the billet. When heating square billets of 150mm x 150mm~200mm x 200mm, there is no restriction on the temperature of entry into the furnace. The heating temperature is 1240 ℃, and the heating time is no less than 1.5-2.5 hours. The total heating time is 3.5-4.5 hours, and the average temperature before leaving the furnace should be maintained for 20-30 minutes.

3.1 Blooming

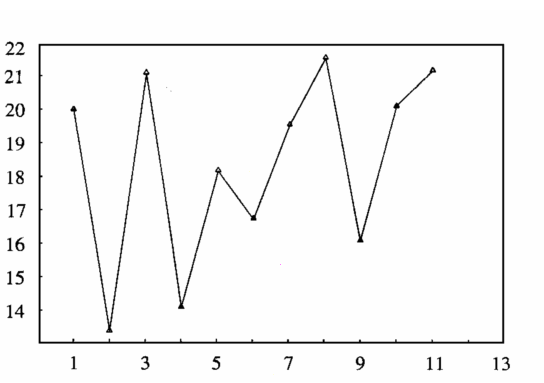

On a two roll reversible blooming mill or a three roll blooming mill, steel ingots are rolled into square billets, round tube billets, or slab billets. The final rolling of a 120mm x 120mm square billet using steel ingot Z with a large cross-sectional size of 570mm x 570mm requires a total of 23 passes through six rows of pass patterns. The first pass pattern requires 10 passes. Similarly, 4 passes are required in both the second and third rows, and 2 passes are required in the fourth and fifth rows. In this pass pattern, different sizes of billet shapes can be rolled to meet the needs of the finished product rolling mill. Only roll one pass in the final square billet hole of the sixth row Z, and flip the steel before entering the odd number of passes. The relative pressure reduction curves for each pass are shown in Figure 1. The average elongation coefficient of this rolling program is 1.145. When designing the rolling program, in order to maintain stability during slotless rolling, the aspect ratio should be controlled to not exceed 1.5.

Figure 1 Reduction rate curve of each pass during the rolling of stainless steel by 850 bloom machine

Special steel production plant Φ The 650 three roll billet opening machine adopts a box shaped conjugate pass layout for the extension pass system in front of the 650kg small steel ingot rolling square billet or rolling round material, in order to save the number of rolling rolls. Through this set of pass patterns, it is possible to roll all alloy structural steels with pearlite structure, ball bearing steels, and austenitic stainless steels, but it is not suitable to roll high-strength steel M2 or W18Cr4V with martensite structure.

The average elongation coefficient of this pass system is 1.17, and the relative reduction of each pass fluctuates greatly. For the first and third passes, the small head of the steel ingot is fed first, without being limited by the biting angle, resulting in a larger relative reduction. For the second and fourth passes, the biting conditions are not good, and the relative reduction decreases (Figure 2).

Figure 2 Reduction rate curves of each pass during stainless steel rolling on a 650mm rolling mill

The first three pass sizes of the lower rolling line in this pass system should not only meet the needs of the small rolling mill for square billets, but also meet the needs of the rolling mill for rolling smaller sized square billets and finished round billets for precision rolling holes. The relative reduction amount fluctuates, which can reduce the number of rollers used, save roller changing time, and improve production efficiency.

In some special steel mills in China, when the quality of special steel continuous casting billets is not completely up to standard, rectangular billets with 240 square meters or corresponding cross-sections are used. Before the precision rolling pass system, a box shaped extended pass system is used, which can maintain small fluctuations in the reduction rate of each pass and relatively uniform deformation.

The composition of box shaped pass is the key to ensuring the rolling stability of various steel grades and achieving smooth surface quality of steel billets. It is appropriate to have a slope of 6% to 18% of the cutting depth on the inclined wall of the lower rolling groove in the box shaped conjugate pass. The slope of the first few inclined walls of Z is 6% to 9%, while the remaining rolling grooves have a cutting depth of 10% to 18%. The bottom width of the lower roll pass must be equal to or less than the height of the front pass by 1-2mm. If the bottom width of the upper roll pass is greater than that of the middle roll, and if the middle roll is greater than that of the lower roll, the slope of the groove of the three rolls in each row of pass must be the same.

3.2 Finished product rolling

The rolling of austenitic stainless steel round steel is mostly carried out using a universal pass system with relatively uniform deformation, while the continuous rolling unit arranged horizontally and vertically adopts a transitional elliptical circular pass system.

When using a universal pass system to roll austenitic stainless steel, special attention should be paid to the wrinkles caused by the double concavities on the surface of the billet when the flat hole rolled piece enters the vertical elliptical hole due to the slight reduction of the arc bottom of the pass. These wrinkles should be brought to the surface of the finished product. The finished hole design is specialized, different from other steel hole types, and requires a 30 ° opening angle. The calculation of the groove width should take the Z maximum positive tolerance value, and a thermal expansion coefficient of 1.015 is more suitable. A reasonable finished product pass design requires measuring the dimensions of the rolled round steel in the ab and cd directions, which must be within the standard tolerance accuracy range.

3.3 Pickling and finishing

After rolling nickel chromium austenitic stainless steel, it needs to be pickled to obtain the desired surface. Some need to increase the size of the round and billet by 3-5mm compared to the required size during rolling, and then perform turning after rolling to remove all surface defects, achieving high dimensional accuracy, that is, one set of dimensional tolerance accuracy, and delivering as silver bright material.

2024 March 3th Week XBRZ Product Recommendation:

Flanged ball bearings have a solid steel flange on the outer ring. This allows the bearing to be more easily located in a housing. The flange can also help to prevent axial movement of the bearing in the event of a thrust load on the bearing. It is easier to maintain the position of a flanged bearing in the housing where a lot of vibration is present.

http://xinzhou.bearingshow.net/product-cat/flanged-ball-bearings/