Time : March 2, 2024

Abstract: The blackening process of bearing stainless steel 9Cr18 was studied. Adding electrolysis process to the blackened 9Cr18 steel bearings significantly improves their corrosion resistance without reducing their hardness. SEM and AES analysis showed that the corrosion resistance was due to the obvious increase of Cr/Fe ratio in the surface facial mask.

Keywords: 9Cr18 bearing stainless steel; Wear resistance; Corrosion resistance; Blackening treatment; electrolysis

With the rapid development of the world economy, higher requirements have been put forward for the corrosion resistance and surface aesthetics of bearing stainless steel. For example, for bearings made of 9Cr18 stainless steel used as fishing gear, in order to be applied in the ocean and improve the success rate of fishing, while maintaining its original wear resistance (hardness), it is required to not produce rust spots and maintain a uniform black color after 96 hours in artificial seawater.

Although using heat treatment methods can achieve better color, the hardness and wear resistance of bearings will be greatly reduced. Although using coatings can achieve satisfactory black color and maintain the original hardness, the bonding force is poor (mechanical bonding), and the coating will fall off shortly after use, causing a significant decrease in the corrosion resistance of bearings and quickly scrapping.

In order to maintain the original hardness (wear resistance) of bearing stainless steel while maintaining a uniform black appearance and high corrosion resistance, this work studied the chemical blackening technology of bearing stainless steel.

1.1 Materials

Using 9Cr18 stainless steel, its chemical composition is (mass fraction): C 1.03%, Mn ≤ 1.00%, Si ≤ 1.00%, P 0.03%, S 0.005%, Cr 17.5%, Fe residue.

1.2 Process screening

Using a mixture of sulfur and chromic acid, containing 100g/L H3PO4900g/L H2SO4100g/L CrO3, with a time of 100 minutes and a temperature of 80 ℃, the obtained film has a dark color and a hardness (HRC) of 56-57.

1.3 Salt spray test

According to the test method in GB/T 10125-1997, 96 h continuous spray test is conducted under the condition of (50 ± 5) g/L NaCl solution, temperature (35 ± 2) ℃, pH 6.5~7.2.

1.4 Water resistance test

According to the GB/T 1733-1993 test method, conduct water resistance tests on the above three samples in deionized water at (42 ± 2) ℃.

2.1 Salt spray test results

The black 9Cr18 stainless steel bearings treated with the above process were subjected to salt spray testing with untreated bearings, and the results are shown in Table 1.

Table 1 Comparison of corrosion resistance between blackened and non blackened 9Cr18 bearings

| Bearing | 12h | 24h | 48h | 96h |

| 9Cr18 | Rust spots appear | Increased rust spots | Obvious rusting | Severe rusting |

| Blackening 9Cr18 | Rust free spots | Rust free spots | Rust free spots | many rust spots |

The test results indicate that although the salt spray test time for the blackened 9Cr18 stainless steel bearings has been significantly increased, there is still a certain gap compared to the requirements of the 96h salt spray test. Therefore, a more corrosion-resistant treatment method is adopted, which is blackening treatment+electrolysis treatment, that is, electrolysis is carried out in a solution of H2SO4-CrO3-H2O additive A. The results of the three states of bearings in the salt spray test are shown in Table 2.

Table 2 Comparison of Salt Spray Resistance Tests for 9Cr18 Bearings with Three Surface States

| Bearing | 48h | 96h | 120h |

| 9Cr18 | Obvious rusting | Severe rusting | Severe rusting |

| Blackening 9Cr18 | Rust free spots | many rust spots | a large number of rust spots |

| Blackening 9Cr18+point solution | Rust free spots | Rust free spots | Rust free spots |

2.2 Water resistance test results

The test results are shown in Table 3. It can be seen that the 9Cr18 stainless steel bearings treated with blackening and electrolysis have good corrosion resistance in water and salt spray tests, which can meet the requirements of users.

Table 3 Comparison of Water Resistance of 9Cr18 Bearings with Three Surface States

| Bearing | 48H | 96H | 120H |

| 9Cr18 | very few rust spots | a few rust spots | a few rust spots |

| Blackening 9Cr18 | Rust free spots | Rust free spots | Rust free spots |

| Blackening 9Cr18+point solution | Rust free spots | Rust free spots | Rust free spots |

2.3 Analysis

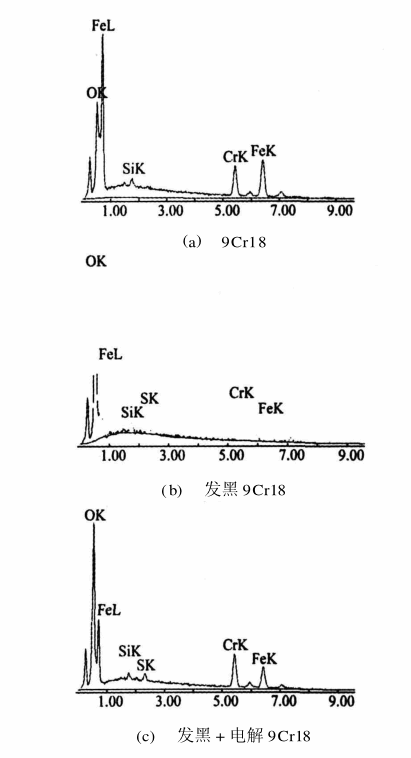

The EDAX energy spectrometer analysis spectra of three different surface states of 9Cr18 stainless steel bearings are shown in Figure 1. It can be seen that the Cr/Fe ratio of three different surface facial mask has changed greatly. The Cr/Fe of 9Cr18 stainless steel without blackening treatment is less than 1, while the Cr/Fe of 9Cr18 stainless steel with two blackening treatments is greater than 1.

Figure 1 EDAX energy spectrum analysis results of 9Cr18 stainless steel bearings with three different surface states

Auger electron spectroscopy analysis shows that the Cr/Fe ratio in the surface facial mask of 9Cr18 stainless steel is about 0.5, while the Cr/Fe ratio in the two blackened surface facial mask of 9Cr18 stainless steel is about 1.5, which is consistent with the analysis results of scanning electron microscopy energy spectrum analysis. In addition, the results of Auger electron spectroscopy analysis show that the thickness of the surface facial mask layer of the electrolytic corrosion resistant 9Cr18 stainless steel is significantly greater than that of the non electrolytic blackened 9Cr18 stainless steel, which indicates that the corrosion resistance of the former is better than that of the latter.

(1) The blackened 9Cr18 stainless steel bearings can significantly improve their corrosion resistance.

2024 March 1st Week XZBRG Product Recommendation:

The structure of deep groove ball bearing is simple, and it is easy to achieve higher manufacturing precision compared with other types, so it is convenient for series and mass production; The manufacturing cost is also low, and the use is extremely common. Deep groove ball bearings are the most widely used bearing type and are extremely versatile. They have low friction and are optimized for low noise and low vibration to achieve high speeds.

http://xinzhou.bearingshow.net/product-cat/deep-groove-ball-bearings/