Time : Октябрь 8, 2025

If you’ve ever shopped for a PC fan, a powerful blender, or even some power tools, you might have stumbled upon the terms “Ball Bearing” and “Sleeve Bearing” in the specifications. They sound technical, but understanding the difference is key to choosing a product that lasts and performs well.

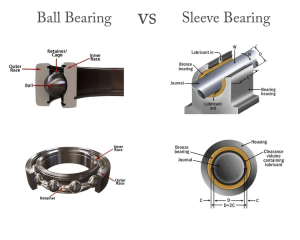

In simple terms, the bearing is the component that allows a shaft (like a fan’s rotor) to spin smoothly with minimal friction. The type of bearing used has a huge impact on noise, lifespan, cost, and durability.

So, let’s break down this classic engineering matchup.

How it Works: Imagine a metal shaft spinning inside a sleeve or a tube filled with a thin layer of oil. That’s essentially a sleeve bearing. It’s a simple, low-friction system that relies on hydrodynamic lubrication—the spinning motion itself creates a film of oil that prevents metal-on-metal contact.

The Pros:

Cost-Effective: Sleeve bearings are cheap and simple to manufacture, making them the go-to choice for budget-friendly products.

Whisper Quiet: At lower speeds and when they’re new, sleeve bearings are incredibly quiet. This makes them a popular choice for home/office PC fans where noise is a primary concern.

Vibration Damping: The oil film can absorb minor vibrations, leading to smoother operation.

The Cons:

Shorter Lifespan: This is the biggest drawback. The oil can slowly evaporate or seep out over time, especially in high-temperature environments. Once the oil is gone, friction increases, leading to wear and eventual failure.

Not for High Speeds: They are less stable at very high rotational speeds.

Poor Horizontal Performance: Sleeve bearings don’t like to be mounted horizontally (like on the side of a PC case). Gravity can pull the shaft to one side, causing uneven wear and a much shorter life. They work best in a vertical orientation.

Best For: Budget-conscious builds, low-noise applications in a vertical position, and devices that aren’t expected to run 24/7 for years.

How it Works: This one is more intuitive. A set of hardened steel balls rolls between an inner and outer race, allowing the shaft to spin. This rolling motion creates much less friction than the sliding motion of a sleeve bearing.

The Pros:

Exceptional Longevity: Ball bearings are built to last. They are much more resistant to wear and tear and are less dependent on lubricant not evaporating. Their lifespan is often double or more that of a sleeve bearing.

High Durability & Speed: They can handle higher rotational speeds and are more robust, making them ideal for high-performance applications.

Mounting Flexibility: Unlike sleeve bearings, ball bearings aren’t fussy about orientation. You can mount them vertically, horizontally, or at an angle without affecting their lifespan or performance.

Better for High Temperatures: They generally perform more consistently in hotter environments.

The Cons:

Higher Cost: The more complex manufacturing process makes them more expensive.

Potentially Noisier: While modern ball bearings are very quiet, they can produce a very slight high-frequency “whirring” or “rolling” noise that some sensitive ears might pick up, especially as they age.

“Click of Death”: If a ball bearing fails, it can often start making a distinct clicking or grinding sound before it seizes completely.

Best For: Servers, workstations, gaming PCs, high-performance appliances (like blenders), industrial equipment, and any application where reliability and long-term performance are critical.

So, which bearing wins? As with most things in engineering, the answer is: “It depends.”

Choose a Sleeve Bearing if: Your priority is low initial cost and maximum silence for a standard-use desktop computer, and you can ensure it’s mounted vertically. They are a great budget option for light to moderate use.

Choose a Ball Bearing if: You need maximum reliability, long life, and durability. This is non-negotiable for servers, gaming rigs, high-airflow situations, or any device that will be running for long hours. The slightly higher cost is a wise investment for peace of mind.

Pro Tip: In the world of PC cooling, you’ll also find advanced bearing types like Rifle Bearings and Fluid Dynamic Bearings (FDB), which are essentially highly refined and superior versions of the sleeve bearing concept, offering a great balance of quiet operation and long life. But when you see the classic choice between standard Sleeve and Ball, you now have the knowledge to make the right call.

Next time you’re buying a fan or an appliance, take a quick look at the specs. That small detail about the bearing can make a big difference in how long and how well your device performs.

Let me know in the comments: Which type of bearing is in your PC’s most important fan?